FLOOR PATCHING

Industrial RCC floors often get damaged due to the all kinds of mechanical and chemical wear. This results in formation of several potholes or patches. Duromax has a range of FloorPatch compounds that are highly durable and easy to use.

WATERPROOFING

Duromax has years of experience and excels at all set of works required to waterproof the roof. Expert visit to the facility is necessary to inspect the condition of the roof.

GANGWAY MARKING AND YELLOW LINING

Challenge faced by floor markings is severe abrasion due to heavy traffic. To withstand the same, marking paint must be hard and adhere well to the substrate. Duromax Floorcon is best suitable for the conditions:

Two coats of: Duromax Floorcon

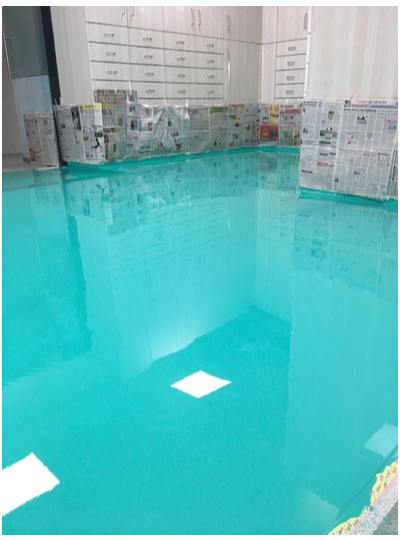

CHEMICAL RESISTANT FLOORING

Epoxy based flooring systems in general have good resistance to mild chemicals. Duromax has developed high chemical resistant floors without compromising on aesthetics.

HEAVY DUTY TRAFFICABLE FLOORING

High resistance to abrasion caused by traffic is brought by single thick monolithic layer of epoxy along with coarse aggregates.

IMPACT RESISTANT FLOORING

Epoxy based flooring systems are known to be brittle. However, with years of research, Duromax has developed highly flexible and tough floorings.

ALL ROUND FLOOR PROTECTION

Based on novel technology especially recommended for both interior and exterior cement bound floors, Duromax Hybrid Flooring is a two-layer system of about 100 micron thickness:

REINFORCEMENT OF CONCRETE

Concrete structure is vulnerable to weathering due to its porosity. With long exposure to sunlight, water and air, the binding strength of concrete reduces. In places where concrete is exposed to acid and chemical fumes, the strength of concrete reduces drastically and a chunk of it comes off in no time.

FOR EXTREME ABRASION AREAS

Areas that involve handling and flow of very hard particles are highly prone to abrasion. Protection of metal in such severe conditions is a challenge in itself. Duromax’s R&D support has produced coating with hardness upto 9 on Mohr’s scale (of hardness) which is only next to diamond. Along with hardness, Duromax products are imparted with high slip property due to reduced coefficient of friction. Abrasive particles tend to flow smoothly through the coated area thereby increasing the longevity.

CERAMIC BASED COATING

Ceramic coating for pump components has been the industrial standard for good time now. Duromax has years of experience in all pump protection coating applications. It’s not only the product which matters but the service by trained Duromax applicators has been the key premise for our success.

HIGH TEMPERATURE CORROSION PROTECTION AND ENERGY SAVINGS

Higher temperatures accelerate the corrosion process to a significant extent. Also, loss of heat from the system is undesirable and needs to addressed. Duromax's corrosion resistant coating protects the system and also saves energy.

HEAT RESISTANT COATING

There are several areas in industries that function at high temperatures below 200°C. Corrosion due to thermal cycle and high temperatures, is highly accelerated and must be addressed in time.

CORROSIVE CHEMICAL CONTAINMENT

Recommended Primer: Duromax Sealerkote SR

Low viscosity surface tolerant primer, Duromax Sealerkote SR is a two component, amine cured epoxy system which cures to give a tough, semi-flexible coat and bonds well to poorly prepared substrates. It is an apt primer for industrial conditions where surface preparation has its limitations.

Recommended Top Coat: Duromax Chemkote CH

Duromax Chemkote CH is a novolac epoxy based high chemical resistance, thick consistent coating which protects metallic as well as non-metallic surfaces against corrosion due to chemicals, acids, alkalis, solvents, oil, vapours and gases. Fortified with abrasion resistant fillers, it is a long term solution to most severe industrial protection applications.

CORROSION PROTECTION IN ACIDIC / MARINE AREAS

In acidic or marine environment, the rate of metal loss is very high due to contact with corrosive media. It is essential to address the area on its merit. Primer coat of Duromax Sealerkote SR arrests the corrosion from the very source. Further coating of Duromax Chemkote ER ensures resistance from external wear actors like acid and moisture.

CORROSION PROTECTION IN WET AREAS

As the rusting process accelerates in presence of humidity, usual enamel and acrylic paints are unable to arrest corrosion from the source. While the upper surface may still hold the glossy enamel layer for some time, but on the inside, the metal surface is gradually reducing in thickness due to corrosion. Keeping in mind, the extensive area of such applications, Duromax has the most cost effective and long lasting solution.

SEEPAGE PROTECTION FOR CONCRETE STRUCTURES

All cementitious walls are porous and susceptible to water absorption. With multiple rain cycles, the absorbed water weakens the concrete structure. The absorbed water soon forms salt which peels off the applied emulsion paint (phenomenon called efflorescence). Duromax has developed a very cost effective product to cease water intake without hindering the breathability of the wall.

COOL ROOF COATING

Sun rays, especially in tropical regions, heat the roofs to great extent. This in turn reduces the life of the buildings and also increases the air conditioning cost. Duromax brings you high SRI coating that reflects sunlight and makes the life below a lot easier.

Request Our Service

Don’t wait in a queue.

Take your service request online!